News Release from windfair.net

Wind Industry Profile of

Zigzag Provides More Yield

Out on the open sea, different rules apply to wind turbines than to those made for onshore use. For example, offshore turbines are not installed individually, but only in farms where the turbines show a different behavior than solo plants. And there are more differences as Ozlem Ceyhan-Yilmaz from the ECN states: “The design of an offshore turbine blade requires a different way of thinking for two reasons. Firstly, there are fewer limitations to noise emission because there are no people living nearby. Secondly, the offshore challenge is to design rotors that will result in the largest power output for complete wind farms.”

Especially in offshore wind farms, the wake between turbines plays a greater role for the yield than in onshore plants. That's why the placement of the individual turbine is of great importance. In order to influence the wake behind the turbines, LM Wind Power and the ECN have developed a new rotor blade tip, which can increase the power generation of a farm between two and six percent. For this purpose, a zigzag shape was designed to increase the turbulence at the boundary of the wake of the plants, thus increasing the overall yield of the farm. This modification, however, makes the turbines louder.

The new intelligent blade tips were installed in a first field test in the ECN test center in Wieringermeer on 2.5 MW turbines. Ozlem describes the test site: “This demonstration was unique. A full-scale experiment in an operating wind farm was performed. Then tips were installed on the blades of the wind turbines in such manner that they could be removed afterwards. The method for installation and removal has been an innovation by itself, and required close cooperation between ECN and LM Wind Power.”

The new intelligent blade tips were installed in a first field test in the ECN test center in Wieringermeer on 2.5 MW turbines. Ozlem describes the test site: “This demonstration was unique. A full-scale experiment in an operating wind farm was performed. Then tips were installed on the blades of the wind turbines in such manner that they could be removed afterwards. The method for installation and removal has been an innovation by itself, and required close cooperation between ECN and LM Wind Power.”

The test results on the 80m rotor blades showed that an increased wind power performance of up to six percent can be achieved through the special blade tips. With a new method, the ECN was also able to measure relatively low power increases. Ozlem makes it clear that the end of research is still far from being achieved and continues to rely on the interaction of the research center with LM Wind Power: “Great results are encouraging to continue designing models and demonstrating blade tips. Together we aim to lower costs of wind energy.”

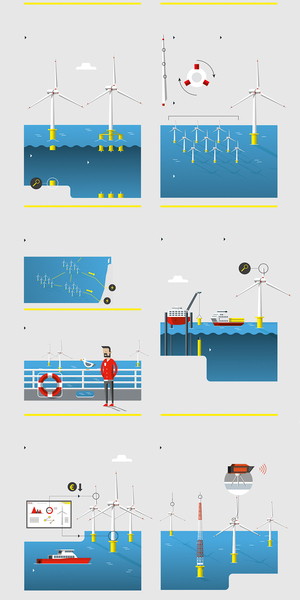

(The graph on the right shows what the ECN is doing in the area of wind energy research.)

The noise levels of offshore turbines thus modified compared to onshore systems have not been published in detail yet. Since there are high requirements of noise reduction with a limit of 160 decibels during the installation of the foundations (at least in Germany), it remains to be seen whether the noise of the zigzag tips has an impact on the local fauna and would therefore have to be regulated.

- Author:

- Katrin Radtke

- Email:

- kr@windfair.net