News Release from Fraunhofer-Institut für Windenergiesysteme IWES

Wind Industry Profile of

Post-approval design changes made possible by smart technology

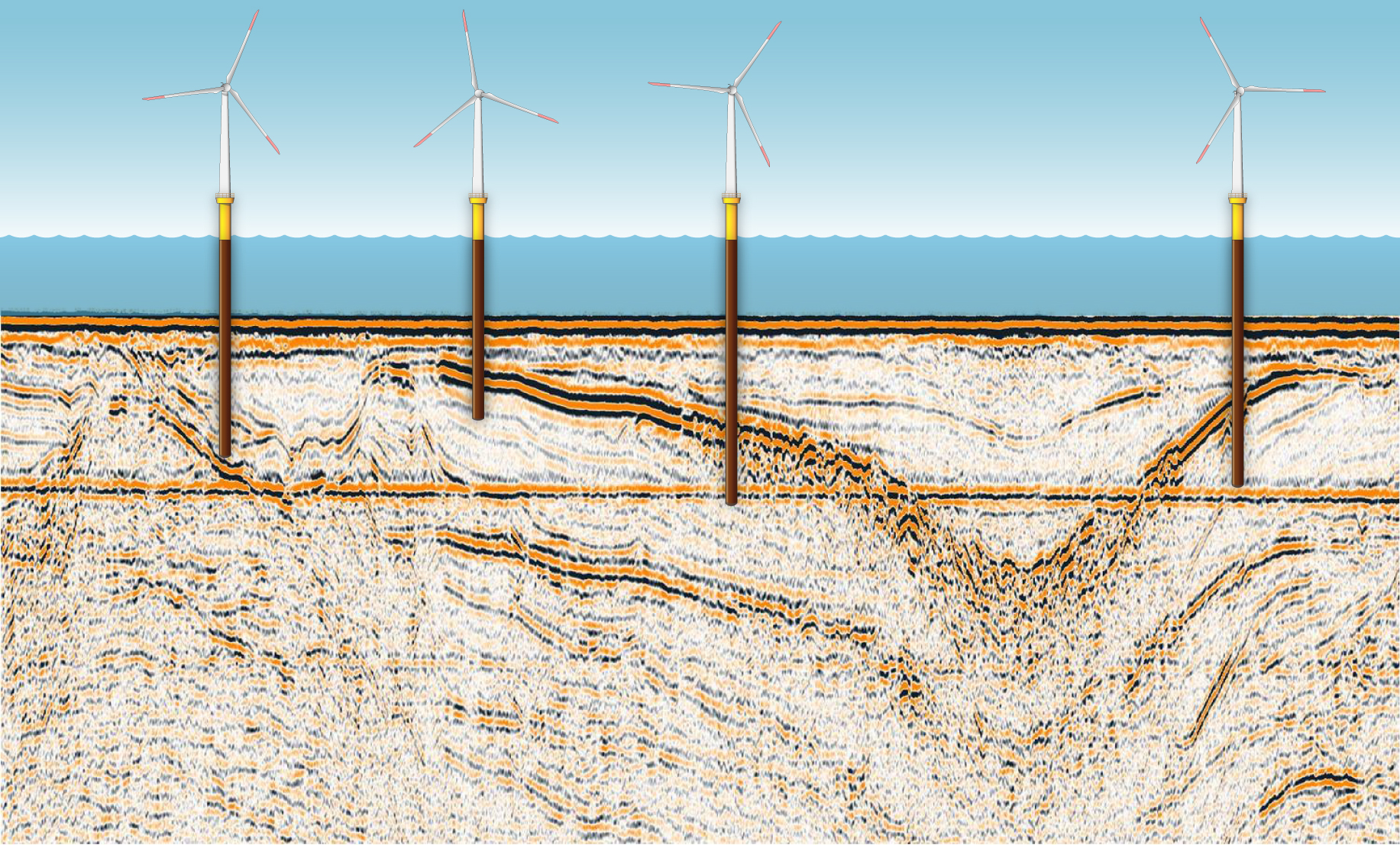

The drilling of new boreholes and pressure sounding in the 39 km2 area would have resulted in longer lead times and would really have squeezed the budget. Seismic surveys using Fraunhofer’s multi-channel seismic system make it possible to look at deeper layers - important, as the support structure of a wind turbine penetrates 50 meters into the seabed. By working up a 3D model of the seabed based on these seismic data, experts at Fraunhofer IWES were instrumental in getting the design of the wind farm approved.

Financial calculations and the use of state-of-the-art technology tipped the scales for the optimization of the layout of the wind farm: Since the early days of planning, the offshore world has evolved considerably, and 6 MW turbines now have a solid offshore track record. The prospect of fewer turbines generating the same planned total capacity of 385 MW is an attractive one, as it cuts the costs of construction, grid connection, and operation. By the time the decision to install the larger class of turbine was taken, the results of 100 drilling operations and 13 pressure sounding tests for the wind farm were already in. Then, to ensure optimal operating conditions and as little wake effects as possible, the layout of the turbines was adapted. This meant that some of the drilling and sounding locations no longer coincided with the new turbine locations. Most of the existing exploration profiles could not be directly applied to the new locations.

The developer had a difficult decision to take: To redo the geological or geotechnical measurements, which would really have impacted on the schedule and the budget, or, alternatively, to procure reliable data to describe the new sites that had been selected, for confirmation by the German Maritime and Hydrographic Agency (BSH). A close-profile, multi-channel seismic survey of the wind farm area and subsequent work-up of a high-resolution 3D layer model provided the basis for the interpolation of local, geological profiles/data at certain points.

With the assistance of a geotechnical expert, the properties of the existing drilling profiles were applied to the new turbine locations for which the seismic survey had been conducted. The subsequently certified method satisfied the technical experts at the BSH. “The recognition by the BSH of the geotechnical survey method combining multi-channel seismics and boreholes highlights the success of this project, which was overseen by a geotechnical expert and certifier. The completion of the final report in an optimal timeframe and without undue cost also shows the potential offered by the application of this innovative, complementary seismic surveying method,” said Martin Ros, Engineering Manager of the Arkona Construction Team, E.ON Climate & Renewables Services GmbH.

A multi-channel seismic system uses acoustic signals to identify the bedding of soil - as starting point for a 3D-profile of the seabed.

The measuring method was developed by Fraunhofer IWES specially to meet the requirements of offshore wind energy and has been in use in the North Sea and Baltic Sea since 2011. It is optimized for use in water depths of less than 100 meters. The signal characteristics coupled with a digital, highly sensitive 96-channel streamer ensure the penetration and reception of the acoustic signal down to the depth of wind turbine foundations. The flexibility of the measuring method makes it possible to move locations even after approval - without the need for expensive geotechnical post-surveys.

- Source:

- IWES

- Link:

- www.iwes.fraunhofer.de/...