Looking at the future of wind – The Selsam Multi-Rotor Wind Turbine

Today's largest wind farms are the size of small towns, made up of turbines 30 stories tall with blades the size of 747 wings. Those behemoths produce a great deal of power, but manufacturing, transporting, and installing them is both expensive and difficult, and back orders are common as the industry grows by more than 40 percent a year. The solution, says inventor Doug Selsam, is to think smaller: Capture more power with less material by putting 2, 10, someday dozens of smaller rotors on the same shaft linked to the same generator.

"The wind-turbine design out there right now is a thousand years old," Selsam points out, as he lets one of his carved wooden blades speed to a blur in the makeshift wind tunnel he's made of the alley behind his Fullerton, California, apartment. He brainstormed his multi-rotor approach in the early '80s, in a fluid-dynamics class at the University of California at Irvine. "The textbook said, this single-rotor turbine design is the most power you can get. I knew then it wasn't right. More rotors equals more power."

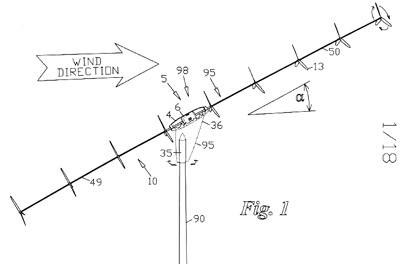

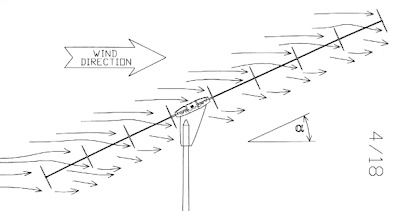

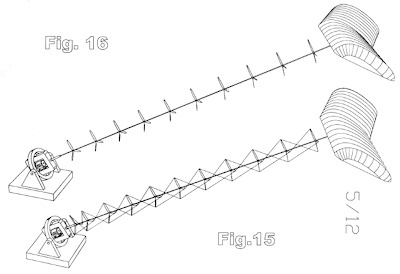

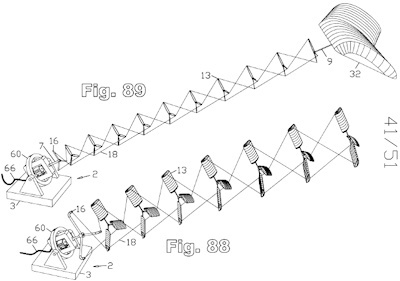

Of course, more rotors also means more-complicated physics. The key to increasing efficiency is to make sure each rotor catches its own fresh flow of wind and not just the wake from the one next to it, as previous multi-rotor turbines have done. That requires figuring out the optimal angle for the shaft in relation to the wind and the ideal spacing between the rotors. The payoff is machines that use one tenth the blade material of today's megaturbines yet produce the same wattage.

Selsam never did graduate from Irvine, but over the next couple decades he kept investigating novel wind designs, and by 1999, after an extended hiatus as a heavy-metal guitarist (he claims that the band Metallica stole its name from his group, Metallix), he turned to wind development full-time. In 2003, he landed a $75,000 grant from the California Energy Commission to develop a 3,000-watt turbine—his seven-rotor design met the challenge—and he has now sold more than 20 of his 2,000-watt dual-rotor turbines to homeowners. He's built them all in his suburban garage.

"We've tested all kinds of wacko things that people think should make a lot of wind energy," says Brent Scheibel, a former turbine tester for General Electric who now runs a wind-testing facility in Tehachapi, California. "The laws of physics take most of them out of the equation very early. Doug's idea is one of the very, very few that I've seen that actually has a strong chance of making strides into the commercial world."

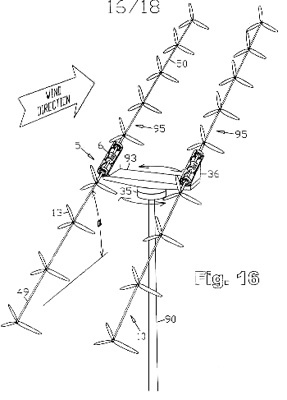

Selsam says two rotors is just a start. Someday he sees his multi-rotor turbines stretching for miles across the sky. "We can go big," he says, "and make turbines using this technique that are way more powerful than anything in GE's wildest imagination."

Technical Overview:

Doug Selsam answers some questions:

Q1: Doug, what makes your multi-rotor wind turbines so special and forward-looking?

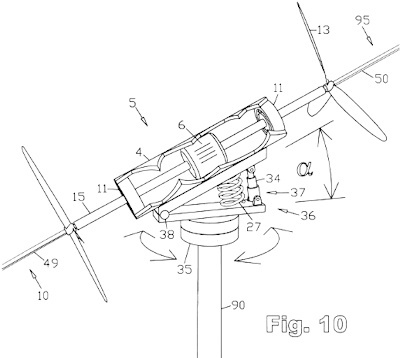

A: Our Multi-Rotor technology neatly solves all classic problems in wind turbine design. Our new design, now proven in small models, combines the power of multiple smaller rotors mounted to a single elongate driveshaft, to give the same power as a single larger rotor, with less cost, weight, and complexity. Smaller rotors weigh less for the swept area, and turn faster, thereby dispensing of the need for a gearbox. Our new design is naturally self-aiming, requiring no dedicated apparatus to achieve this, and is generally simpler, having fewer moving parts, requiring less maintenance. We expect to validate this revolutionary California design, using multiple rotors coupled to a single elongate shaft as being able to harvest more wind energy at less cost than current models which use only a single rotor.

Q2: Doesn't the wind shadow from one rotor inhibit the next rotor from getting wind?

A: That's definitely a factor to consider. Our driveshaft is at an angle from horizontal, with the nose pointing slightly downward so that, with proper spacing, each rotor gets its own wind. In addition, the forward tilt of the rotors tends to direct the wind downward, pulling more fresh wind through the machine from above...

Any slight losses of power from wind shadow effects are more than made up for by the overwhelming combined power of a multiplicity of rotors.

Q3: Can two or more of the Selsam Multi-Rotor Wind Turbines be combined on a rotating frame to form a single self-aiming wind-power-production structure?

A: Yes. Multiple turbines mounted to a single rotating armature are self-aiming as a combined unit. Multiple levels are also possible.

Q4: Is the Selsam Multi-rotor wind turbine well suited for rooftop mounting?

A: Yes! The low profile design makes good use of the flow of air over a roof. The multiple rotors combine for smooth, quiet, relatively vibration- free operation.

Q5: What about the fact that the horizontal axis rotors aren't aimed exactly into the wind, but instead are aimed slightly downward from horizontal? Don't they lose a lot of power?

A: Another good point. Luckily, a slight deviation from the wind direction has almost no effect on a rotor's performance. The offset angle can also be in another plane, such as horizontal, useful in larger installations where rotor size is a significant fraction of tower height.

Q6: What about the bearings? Isn't there a lot of radial loading from the weight and wind loading amplified by the leverage of the length of the shaft?

A: The upwind section of the shaft approximately balances the downwind section. This minimizes radial loading on the bearings. That allows long bearing life.

Q7: Why doesn't it need a tail, or a dedicated azimuthal orientation means of any kind?

A: We feel that since a tail doesn't contribute any power, get rid of it and put on something that does produce power, like more rotors. A conventional tail is like a partner on a tandem bike who refuses to pedal! We simply place the center of aerodynamic drag of the entire driveshaft with its attached rotors slightly downwind of an azimuthal pivot point, and the machine will faithfully stay headed windward.

Q8: What about protection in high winds?

A: Several factors act to protect the machine in high winds: First, at the higher reynolds numbers that come with increasing wind speeds, the length of wind shadows effectively increases, so that upwind rotors will begin to protect downwind rotors. More importantly, the downwind section of the shaft will tend to bend to a more horizontal direction, placing downwind rotors more into the wind shadows of the upwind ones. Finally, the generator and shaft can be resiliently mounted, so that they are blown into a more horizontal orientation by very strong winds, so that overall rotor exposure is reduced, while power output and rpm are maintained. They key to proper behavior at all wind speeds is that progressively more rotor surface is exposed in low winds, and less in high winds. No furling cycle is involved, so there is never a time when no power is generated because of excessively strong winds. The action is also not as radical as furling, and is less prone to "finicky" behavior.

Q9: What designs do you have in mind for the future? Are they also covered by your patents pending?

A: Yes, and the future is wide open. This design is an important advance, yet is still just the tip of the iceberg. Future patent pending designs include atmospherically buoyant versions that incorporate helium-filled or hydrogen-filled kite-like aerodynamic lifting bodies instead of a tower. Others utilize buoyant, inflated rotors. We have much more advanced designs still. We have had preliminary discussions with some NASA personnel indicating that such turbines might find use as easily deployable power sources on Mars.

Q10: Despite all the logical reasons why this new design seems to be a step forward, I'm having trouble accepting it. It seems too simple or something - I can't quite put my finger on it, but it bothers me. Is there any help for someone like me?

A: Innovative designs are often surprisingly simple. Advances in materials science make such progressive designs more practical. Progress inevitably involves change. Just close your eyes and relax, and keep repeating this mantra: "More rotors mean more power".

Q11: Utility-sized Turbines are being made larger all the time. Will yours scale up to Megawatt sizes?

A: So far they are scaling up beautifully. They are surprisingly stable even in very strong winds. We don't see any upper limit yet - further experiments will tell us how big they can get. For a given power rating, say 1 megawatt, our rotors are much smaller, about 1/3 of the diameter or less, and weighing a total of only about a third as much, collectively, with 2/3 less angular momentum. Blade stress considerations would thus be reduced, for a given power rating, using our design. This would suggest that the upper size limit for this design could also be in the megawatt range, and for atmospherically buoyant versions, possibly higher.

Q12: The trend has been going toward low speed, high torque alternators and generators.

A: Only because there hasn't been any other choice, except using a power-robbing, maintenance and wear-prone, heavy, expensive gearbox. By comparison a specially-built, multipole generator designed for low speed, high-torque generator has indeed been an attractive, albeit initially expensive alternative, but a generator made for normal speeds is still preferable, if there is a choice. There's a reason generators have traditionally been made for a faster RPM, given a choice. They can be smaller, and lighter, and simpler, by just turning faster. Also, at a faster RPM, the same power is transmitted at less torque, so the drivetrain can be less robust. The result is a lighter, simpler, more economical installation. When this new design is scaled up, we, too will preferentially take advantage of specially built, multipole generators with many poles for slow, high-torque operation. Our design, however, can be more powerful before it reaches a size where such a specially-built low speed generator is needed.

Thank you Doug for the insight into your new wind turbine technology and vision for the future!

If you would like to receive our Newsletter or find out more about what w3.windfair.net has to offer, please, do not hesitate to contact Trevor Sievert at ts@windfair.net.

w3.windfair.net is the largest international B2B internet platform in wind energy – ultimately designed for connecting wind energy enthusiasts and companies across the globe.

- Source:

- Doug Selsam

- Author:

- Edited by Trevor Sievert, Online Editorial Journalist / by Doug Selsam

- Email:

- ts@windfair.net

- Link:

- w3.windfair.net/...