Editor's Choice - The Ogin Wind Turbine - The New Shape of Energy

OGIN's Difference - Ogin is driven to make affordable, clean energy available to everyone

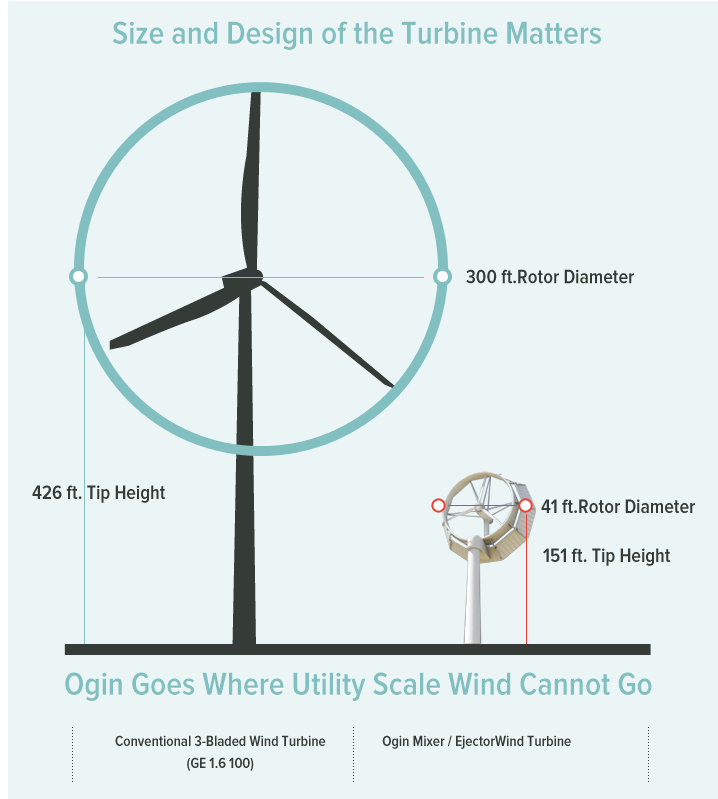

Guided by this mission Ogin is reshaping energy with its first breakthrough, the Ogin Turbine. It’s a smaller, more efficient wind turbine that can go where large turbines can’t – enabling wind energy developers to bring clean energy production closer to consumers.

Innovation is in Ogin’s DNA. Inspired by the latest advances in the aerospace industry, the Ogin Turbine dramatically improves efficiency and power output with its unique shroud and vortex technologies:

- Project development cycles are shortened.

- Lower siting impacts and shorter setbacks simplify permitting challenges.

- Modular manufacturing and off-site subassembly simplify and speed on-site construction.

- Wind arrays can be sited closer to customers and connected directly to local distribution grids, without the need for new long-distance transmission infrastructure.

- For developers, these advances translate into significant cost savings.

- For consumers, it means a new choice.

Today, the Ogin Turbine makes the best form of energy – clean, healthy, inexhaustible energy from renewable resources – more broadly available and more affordable than ever before.

Opening New Markets by Going Where Others Can't - The low-profile Ogin Turbine opens new markets and sites, offering wind energy developers new opportunities to grow their operations and sales. The high efficiency of the Ogin Turbine enables profitable development in a wide range of wind regimes, whether to meet local or regional needs. Projects using Ogin Turbines can be accommodated easily within existing road and power networks. Modular design and smaller-size components enable turbine transport in standard flatbed trucks without the need for costly road upgrades, permits, or escorts.

Utility-Scale Economics Make Wind Affordable - The Ogin Turbine brings unprecedented efficiency to the mid-scale turbine market. Ogin’s innovative design yields a 50% gain in annual energy production from a 100kW-class turbine, and dramatically higher energy output per unit of swept area from its compact, high-speed rotor. A simplified gearless direct drive system and critical damped turbine shroud translate into reduced stress on moving parts, longer service intervals and major O&M savings. The result: utility-scale economics are now available in a more flexible 100kW machine. In addition, current federal law provides Ogin Turbines with access to a stable Business Energy Investment Tax Credit through 2016. With this credit, the Ogin turbine compares even more favorably both to conventional energy and utility turbine-based projects that face an uncertain subsidy future.

OGIN's Technology - Ogin brings a quantum gain in wind turbine performance.

Conventional wind turbines have greatly increased in size and height in recent years, but their fundamental design hasn’t changed much in decades. In fact, today’s standard turbines are based on the same physical principles as 18th century windmills. The Ogin Turbine is different. Its unique shroud design takes advantage of the latest advances in the aerospace industry to change physical airflow patterns through and around the turbine. Annual energy output per kW of rated capacity is increased by 50%, while peak energy output from the ultra compact rotor is increased by up to three times per unit of swept area. The result is a quiet, compact 100 kW turbine that outperforms any other midscale turbine on the market.

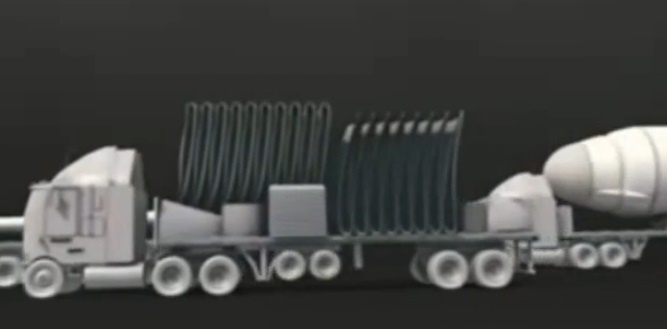

Beyond the turbine itself, Ogin is also forging wind industry breakthroughs in the processes of manufacturing, transportation logistics and on-site assembly. The Ogin Turbine’s modular design enables highly-automated mass manufacture of parts. These are sub-assembled at a centralized facility and can be delivered over ordinary roads in standard flatbed trucks for rapid on-site final assembly. The bottom line: shorter project development and construction timelines, and a more cost-effective way to deliver the benefits of wind energy to consumers.

Bringing Mass Production to Wind - Ogin Turbines are the first in their class capable of being mass-produced, with a modular design that is easy to ship and assemble on-site. Smaller component sizes enable shipment in standard flatbed trucks – eliminating many logistical headaches. The bottom line: Projects can rapidly scale with less working capital.

Faster, Cost-Effective Construction - The Ogin Turbine is designed with easy, fast construction in mind. Turbines are shipped in what is essentially a mobile factory. Components can be assembled quickly with much smaller, less expensive cranes than traditional turbines. Following site preparation, individual turbines can be erected in a matter of days instead of weeks. Site preparation itself is easier because there is no need to widen existing roads. Turbines are shipped in standard 40-foot containers and can be brought in on standard roads. The bottom line: faster, more cost-effective construction of clean wind energy projects.

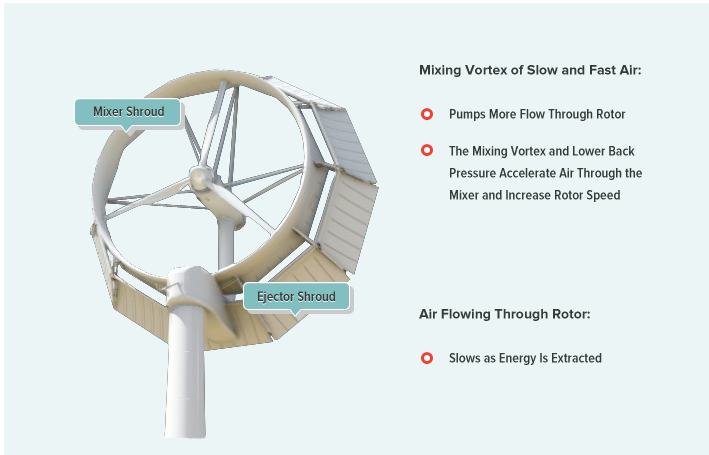

Mixer-ejector Technology Means Greater Efficiency - Conventional turbines operate by posing resistance to wind. Well-established physical laws dictate that nearly half the available energy approaching an open-bladed turbine is diverted around the rotor face. This lost energy generates turbulence instead of usable electricity. Ogin Turbines are fundamentally different. The mixer-ejector shroud system functions as a static pump that changes the pattern of airflow through and around the turbine.

- The mixer shroud, surrounding the rotor plane, creates vortices of slower and faster airflow that mix out turbulence and reduce turbine backpressure. Wind accelerates through the rotor, increasing power extraction. Lower turbulence around the turbine lessens mechanical strain and reduces long-term O&M costs.

- Exit air passes from the mixer into the larger ejector shroud. At this stage, additional outside air is introduced, equalizing pressure with exterior wind passing by the turbine. The ejector spreads the wake over a larger area, reducing turbulence aft of the turbine. This rapid wake mitigation allows turbines to be positioned closer together.

If you like to receive our Newsletter or find out more about what w3.windfair.net has to offer, please, do not hesitate to contact Trevor Sievert at ts@windfair.net.

w3.windfair.net is the largest international B2B internet platform in wind energy – ultimately designed for connecting wind energy enthusiasts and companies across the globe.

- Source:

- Ogin

- Author:

- Edited by Trevor Sievert, Online Editorial Journalist / by Ogin Staff

- Email:

- ts@windfair.net

- Link:

- w3.windfair.net/...