Product News - Field-assembled turbine blade from Wetzel Blade

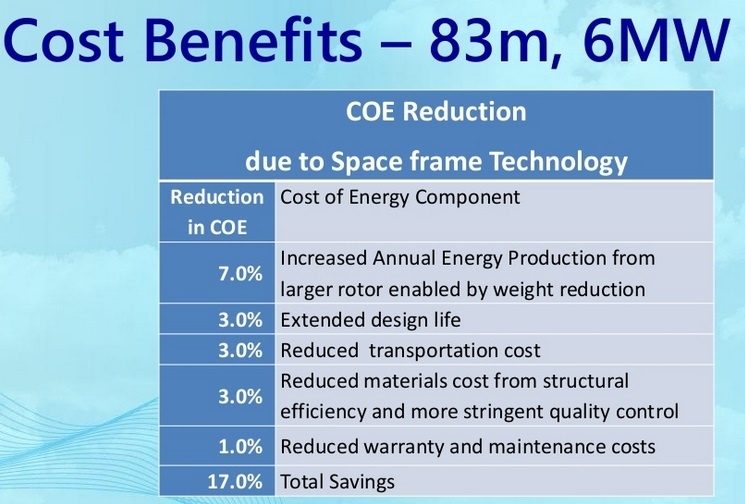

The Pflugerville, Texas-based company's blade concept won a 2014 Clean Energy Venture Award at the US Department of Energy's (DOE) National Renewable Energy Laboratory's NREL Industry Growth Forum in October. Wetzel was presented with an Outstanding Venture Award for its work on the field-assembled turbine blade which is designed to boost production capacity, reduce transportation costs, and deliver longer service life than current blade designs.

The Wetzel wind turbine blade is based on a space frame design and features independently fabricated pultruded fibre reinforced plastic (FRP) spars. The parts are sized for easy transport and field assembly.

Kyle Wetzel, CTO/Founder of Wetzel Blade, explains that this concept emerged from a project that the company's parent company, Wetzel Engineering, was involved with in China. "We were engineering a 100 m blade for a 10 MW turbine and wanted to eliminate shell panel buckling as a design driver. The balsa requirements presented another challenge – almost 10,000 kg of this expensive core material absorbing ~6000 kg of epoxy.” “Because of our involvement with the entire turbine lifecycle, we understand that to make a real shift in the economics, a blade design must generate more electricity, cost less to build and maintain, and be more efficient to transport and install. The industry is hungry for a solution that delivers on all those points.”

Kyle Wetzel, CTO/Founder of Wetzel Blade, explains that this concept emerged from a project that the company's parent company, Wetzel Engineering, was involved with in China. "We were engineering a 100 m blade for a 10 MW turbine and wanted to eliminate shell panel buckling as a design driver. The balsa requirements presented another challenge – almost 10,000 kg of this expensive core material absorbing ~6000 kg of epoxy.” “Because of our involvement with the entire turbine lifecycle, we understand that to make a real shift in the economics, a blade design must generate more electricity, cost less to build and maintain, and be more efficient to transport and install. The industry is hungry for a solution that delivers on all those points.”

Today’s wind turbine blades are fully assembled in factories and transported in one piece to wind farms. In the US, 58 m blades are the largest that can be transported in a traditional manner using large trailers with escort vehicles. The logistics involve coordinating drivers, escorts, permits and specialised equipment – which generally amounts to 3-5% of the total installed cost of each turbine.

The value proposition of the Wetzel modular blade is to enable turbines to generate 7% more average annual energy, reduce blade transportation costs by 75%, and deliver 50% longer service life compared to current generation blades.

The value proposition of the Wetzel modular blade is to enable turbines to generate 7% more average annual energy, reduce blade transportation costs by 75%, and deliver 50% longer service life compared to current generation blades.

Wetzel Blade is currently in the structural testing phase with plans to demonstrate a sub-scale prototype in early 2015. The project has been partially funded through an SBIR/STTR award from the Department of Energy.

View a presentation of Wetzel Blade's technology here.

Clean Energy Venture Award winners receive commercialisation support to help increase their chances of becoming commercially successful.

For more information on this article, to recieve our Newsletter or get to know more about what w3.windfair.net has to offer, please do not hesitate to contact Trevor Sievert at ts@windfair.net

w3.windfair.net is the largest international B2B Internet platform – ultimately designed for connecting wind energy enthusiasts and companies across the globe!

- Source:

- Wetzel Blade

- Author:

- Edited by Trevor Sievert, Online Editorial Journalist / by Wetzel Blade Staff

- Email:

- ts@windfair.net

- Link:

- w3.windfair.net/...