News Release from GfM Gesellschaft für Maschinendiagnose mbH

Wind Industry Profile of

GfM presents a new Condition Monitoring System

Sensors can be easily screwed onto a mounting base, a flat, previously glued steel cylinder. Cables are professionally laid and placed on the Peakanalyzer. The software guides you through the configuration and commissioning without the need for special diagnostic knowledge. Because the Peakanalyzer requires no learning phase, it is immediately ready for use.

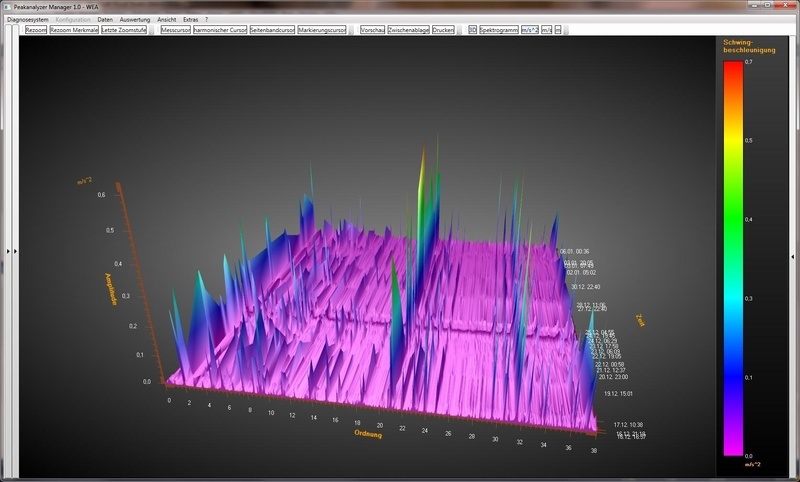

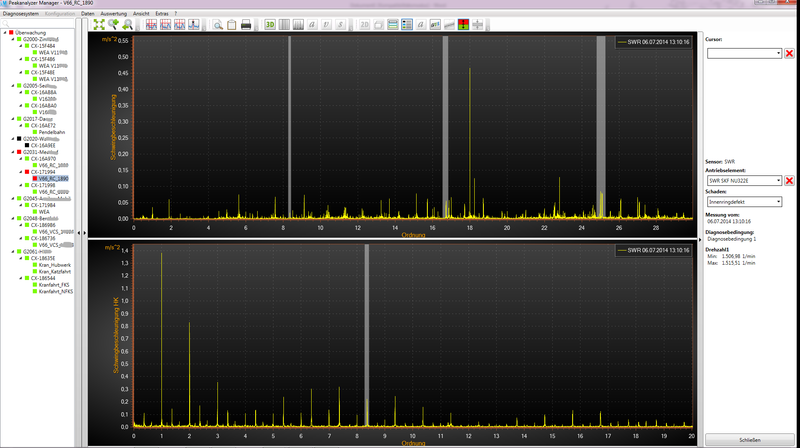

The support of the CMS requires little personnel effort and can be done by the operating staff. Reports about detected irregularities are clearly displayed as plain text messages. For an overview that is usually sufficient. Only for the final maintenance decision it can be useful to analyse the spectra and envelope spectra. Therefore a large variety of tools, such as the waterfall diagram and spectrogram, the representation of individual characteristics over time, useful cursor functions and much more, is available.

Picture: Waterfall display of order spectra

Picture: Order spectrum and envelope curve of the detected roller bearing inner race damage

Offline vibration diagnosis – a service of GfM

It´s very simple: We come to you, install a few sensors at the drive and start data collection. The recorded signals were stored and afterwards, spectra and envelope spectra were formed. These spectra were analyzed with respect to irregularities. The results are summarized in a report.

Picture: PeakStore, the eight-channel offline data collector

Of course, you can also perform the data collection by yourself. For this, you need the eight-channel data collector PeakStore.

- Source:

- GfM

- Email:

- mailbox@maschinendiagnose.de

- Link:

- www.maschinendiagnose.de/...