DONG Energy and Oxford University collaboration - bringing down the cost of offshore wind

Professor Guy Houlsby delivered the 54th Rankine Lecture on Interactions in Offshore Foundation Design on Wednesday 19 March. The Rankine Lecture is the most prestigious of the invited lectures in geotechnics.

DONG Energy Wind Power has been developing a strong connection with the Department of Engineering Science at Oxford University since 2007 and the Professor will reference some of the work in his lecture.

The topic that he has chosen is highly relevant to DONG Energy’s goal of cutting costs by 35 – 40% for projects getting the go-ahead in 2020 as he explains:

“The proportion of the project capital that goes on the foundations in an offshore wind farm is quite high. It can be around 20 percent. If we can get that cost down by 25 percent then the overall cost of the wind farm can be reduced by 5 percent which is quite an impact on getting to that target.”

“There are lessons to be learnt from the oil and gas industry but there are also big differences where we need to continue to innovate. For example, an offshore oil rig is a one-off, bespoke structure with a foundation that probably costs very little in relation to the overall project. An offshore wind farm has many foundations so more of a production line is needed and they must be robust and repeatable in different ground conditions.”

One of the areas that Professor Houlsby’s lecture will cover is monopile foundations, which are also the subject of his work in collaboration with Imperial College London and University College Dublin on the PISA Project. The PISA Project is a Joint Industry Project being led by DONG Energy through the Carbon Trust’s Offshore Wind Accelerator, and includes Iberdrola, RWE, SSE, Statoil, Statkraft, Vattenfall and recently joined Alstom as partners.

Partnerships with several companies and academic institutions are vital in cutting the cost of offshore wind.

There needs to be an industry wide effort to achieve the goals of cost reduction – it’s not something that one industry partner can do alone.

“PISA is a project looking at the traditional monopile foundations and is an excellent way to collaborate with DONG Energy and the wind industry” says Professor Houlsby. “It’s a great way for us to do research because we have industrial partners on board who can help with full size demonstrations. We lead on the research programme but are not tasked with the large scale test. Sometimes it can take a while to arrive at an agreed programme and final technology specification but it works well for both parties.”

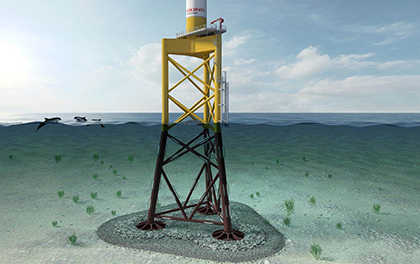

Illustration: DONG Energy

Suction buckets

To date, almost all of DONG Energy’s wind farms have used the standard solution of the monopile foundation:

“The monopile is always going to be an attractive solution because we can make it work just about anywhere. That gives you more flexibility than the caisson” says Houlsby.

DONG Energy and the Carbon Trust OWA are also researching the so called Suction Bucket Jacket, which Professor Houlsby is also interested in. DONG Energy will install a demonstration of the technology this year at their German project Borkum Riffgrund 1.

“I’ve been working on caisson research for more than 10 years now” says Professor Houlsby. “Recently the caisson was being heralded as a universal solution for offshore foundations. I’d argue it’s not going to work everywhere, but at the right site, they are a great solution. The main benefit is that you don’t have to drive them into the ground so the environmental impact is less. There’s also a saving on installation as the equipment you need is much cheaper.”

His final word is on a third type of foundation that he is now researching, helical piling. If a monopile is a nail being hammered into the seabed, a helical pile is screw that needs a giant screwdriver to get it in place.

“We’ve already got helical piles onshore, so the technology exists. It’s now about upscaling that for offshore wind. We will need a pile that is 4 times the size of an onshore one, so something around 2 meters in diameter. It’s a technology that is possible but needs new equipment for installation. I think it will have a real future in offshore wind.”

- Source:

- DONG Energy

- Link:

- www.dongenergy.com/...