News Release from windfair.net

Wind Industry Profile of

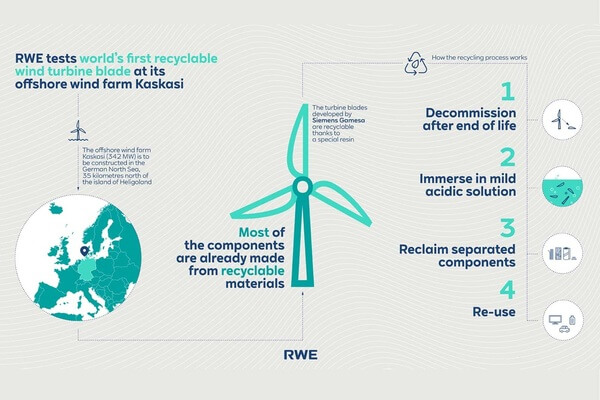

Recyclable rotor blades for German offshore wind farm

Turbine manufacturer Siemens Gamesa and developer RWE will test a new product at the German offshore wind farm Kaskasi. Several of the 38 wind turbines in total will be equipped with RecyclableBlade, the world's first recyclable rotor blades for commercial use at sea. This technology makes it possible to separate the materials in the rotor blade at the end of its service life to enable recycling for new applications.

The first six RecyclableBlades, each 81 meters long, have already been produced at Siemens Gamesa's rotor blade manufacturing facility in Aalborg, Denmark, the company said.

"The time is overripe to tackle the climate emergency ambitiously and holistically. The RecyclableBlade is another concrete example of how Siemens Gamesa is moving forward in technological development and protecting our livelihoods. As a pioneer of the circular economy in the wind industry, we are celebrating this important milestone today," said Andreas Nauen, CEO of Siemens Gamesa.

There are established recycling processes for many wind turbine components, such as the tower and nacelle. The composite materials used in the rotor blades have been more difficult to recycle. Thanks to the use of a new resin, the RecyclableBlade from Siemens Gamesa is the first of its kind that can be recycled at the end of its life cycle. In the process, it is manufactured using the proven IntegralBlade process, just like the current standard rotor blades. It points the way to a future where full recyclability of wind turbines will be a market requirement.

Various new technologies are being tested at the Kaskasi offshore wind farm (Image: RWE).

But the use of recyclable rotor blades is just one example of how RWE is driving technological advancements in the offshore wind industry. At the 342-MW Kaskasi wind farm, the company is installing special steel collars around three monopile foundations for the first time. The so-called "collared monopile" was designed on the basis of a patent developed by RWE and is placed almost at ground level around the monopile. The space between the collar and the monopile foundation will be filled with jointing material, known as grout, to create a stable connection. RWE will conduct accompanying tests to prove that the steel collar improves the behavior of the foundation structure compared to standard monopiles.

In addition, Kaskasi will be the first offshore wind farm in the world to use an improved installation method to place the wind turbine foundations to their final depth in the seabed. The use of innovative vibratory pile driving technology is expected to enable significantly faster and gentler installation while reducing noise. This is of particular benefit to the marine environment. The pilot application at Kaskasi is being supported by an extensive research project funded by the German Federal Ministry for Economic Affairs and Energy.

- Author:

- Windfair Editors

- Email:

- press@windfair.net

- Keywords:

- Siemens Gamesa, RWE, developer, manufacturer, recycabl, rotor blade, turbine, offshore, wind farm, Germany, coast, innovation