News Release from Windmesse.de

Wind Industry Profile of

Windfair Interview: JDR Cables

Windfair: Please give us a brief insight into your company: Where are you based, how many employees do you have, do you operate worldwide, etc.?

JDR is based in the UK with around 500 employees worldwide from Europe, Houston and Brazil in the Americas to Thailand in the Far East.

JDR’s focus is offshore energy production; we design and manufacture inter-array cables and accessories for renewables operators and umbilicals and power cables for oil and gas markets. Our Global Services group provides pre-commissioning, installation and maintenance support, including specialist field services for offshore wind farms.

Our focus is the wind energy industry. What do you provide for this special industry branch?

Our focus is the wind energy industry. What do you provide for this special industry branch?

JDR is a pioneer in inter-array cables – we have worked on some of the world’s largest offshore wind projects from Greater Gabbard and London Array in the UK to Meerwind in Germany. We offer a complete package for renewables operators from design to manufacture and field service support. In addition to a growing range of inter-array cable designs, we provide accessories including pulling grips, hang-off, connectors and fibre optic splice boxes.

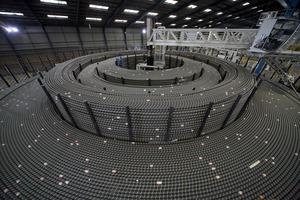

Our specialist dockside manufacturing facility in northern England can deliver individual cables up to 4,000 tonnes, with carousel storage and direct vessel loadout.

When did you decide to enter the offshore wind industry? You had experiences in the offshore sector before by working for gas and oil companies. Did that make it easier to adjust to the offshore wind energy industry?

JDR has over 20 years’ experience in oil and gas markets. We entered the offshore wind market in 2005 with the Beatrice demonstrator project and won our first major offshore wind project in 2007/8 for Greater Gabbard. Greater Gabbard was the first project manufactured by JDR following a £35m+ investment in a new large scale manufacturing facility on Hartlepool dock.

Our oil and gas track record was an important factor. So was our ability to understand the different challenges being faced by renewables operators and adapt our capabilities to support their rollouts.

Are there any differences between working for the oil and gas industry or the wind industry?

Are there any differences between working for the oil and gas industry or the wind industry?

All customers want a well-designed product that is fit for purpose. We pride ourselves on achieving this – we have a zero cable failure rate in service track record for all our projects including our offshore wind projects. JDR has delivered comprehensive product systems for some of the world’s largest offshore wind projects in the UK and Germany and helped the client to be on budget.

What are the current projects of JDR Cables? Do you have any new products in the pipeline?

We have recently announced a sequence of new project wins. These are for Dudgeon in the UK and Sandbank and Nordsee One in Germany.

Our new project wins are driving new product developments too. For the Sandbank project we are developing a new coilable 630mm2 copper core cable. The Nordsee One offshore wind farm will be the first deployment of JDR’s new aluminium core inter-array cable design. Both developments will support offshore wind cost reduction programmes.

The UK is already world leader in the offshore wind sector. Where do you think the upcoming markets are located – and are you planning on entering them by building a factory abroad for example?

The UK and Germany are the primary global markets for large scale offshore wind. Both markets have significant opportunity for growth. We see markets developing in both Northern and Southern Europe. Outside of Europe there are opportunities, for example in the US, Taiwan and Japan; these are mostly early stage developments.

Our main manufacturing facility is on the North-East coast, with direct access to North Sea shipping lanes. It is ideally positioning for European projects and product manufactured here is shipped to projects all over the world from North America to Australia.

Offshore wind is still considered by many people as being too expensive. What do you think is necessary to bring down costs permanently? And what can/must politics contribute/provide?

Offshore wind is still considered by many people as being too expensive. What do you think is necessary to bring down costs permanently? And what can/must politics contribute/provide?

Offshore wind is a relatively new form of power generation compared to fossil fuels; it’s still in the early stages of technology development and large scale rollout.

The industry has already made important steps in reducing cost, it’s a learning cycle. The knowledge built through major wind farm developments so far is feeding back into research and development. JDR is looking at cost-reduction opportunities on a number of fronts. This includes UK government supported work on 66kV cables, investigations into how dynamic ratings could reduce cable connector sizes and material costs and how strain sensing fibre optics can be used to minimise installation issues and new aluminium cable cores. The JDR team is also looking at how it can transfer proven oil & gas approaches to renewables, for example pre-terminated inter-array cables and installation support and maintenance.

Cost reduction is dependent on technology investment and scale. Governments must provide clarity on their long-term energy vision and demonstrate consistency in policy. This creates confidence within the industry, provides certainty around the volume of developments, which in turn attracts private investment the industry needs.

Cost reduction is dependent on technology investment and scale. Governments must provide clarity on their long-term energy vision and demonstrate consistency in policy. This creates confidence within the industry, provides certainty around the volume of developments, which in turn attracts private investment the industry needs.

Copyright Pictures: JDR Cables

- Author:

- Katrin Radtke

- Email:

- press@windfair.net

- Link:

- www.jdrcables.com/...