News Release from Hauff-Technik GmbH & Co. KG

Wind Industry Profile of

Hauff-Technik: Challenges and professional solutions for sealing of power cables in foundations of onshore wind turbines

Not only have the dimensions increased with the performance, but the requirements concerning the technical equipment and particularly its reliability have also increased. In many respects, technical excellence has thus been achieved.

If, however, we look at such a turbine in terms of protection against possible ingress of water or oil leakage in the foundation areas, we find that the construction style particularly of these safety-related areas has not developed to the same extent as the overall system.

Ingress of water in the foundations of a wind turbine

Moisture and water in particular can develop destructive forces in all kinds of buildings. And we are not talking about water damage that can be repaired by using a bucket and floor cloth, but damage that will permanently paralyse the entire system and incur enormous costs to resume operations. It may thus happen that in power supply buildings, e.g. in transformer stations, switch gear stations, substations or precisely in the foundations of wind turbines, electrical short-circuits caused by moisture and water may cause an entire system to collapse.

At the early stages of wind turbine construction, due to the sizes of the plants at that time which were often below 1 MW, the necessary transformer stations were placed in so-called transformer stations made of concrete or steel plate housings outside the tower due to lack of space. There was and is a large number of standards and guidelines for the construction and operation of these transformer stations that must be complied with since transformer station, switchgear and low-voltage distribution must be protected against dirt, water, moisture etc. The cable entry points, i.e. the openings in the building wall of the transformer station, in addition to a watertight station body, are an important detail of this necessary protection.

Due to many years of sometimes very costly experience, the operators of energy distribution grids take great care to ensure that particularly water has no possibility to leak into the transformer station and cause damage to the technology up to and including the complete breakdown of the plant. However, surface water, rain water or backwater are not the only dangers to the equipment. Reptiles and small rodents that want to use these openings as an access point to a presumably dry and warm place to stay, and upon contact with a power busbar may cause immense damage due to failure of the plant, should not be underestimated.

For these reasons but not only for these reasons, the design of the foundations of wind turbines should be given highest priority. After all, safety is not limited to the interior of a building but must more and more often also meet the requirements of environmental and water protection in the immediate surroundings.

In the case of an accident of the transformer with a possible leakage of transformer oil, substations and transformer stations built within or adjacent to water protection areas must not pose a threat to the groundwater. Any leakage of oil from a transformer station must therefore be prevented using state-of-the-art measures. As a matter of fact wind turbines are often built in natural environments which demands the highest level of caution in order to permanently and safely rule out any longterm damage to the groundwater. This makes sense as renewable energy should not be generated at the expense of the environment.

In order to rule out these hazards, appropriate gastight and watertight, rodent-resistant and transformer oil-tight cable entries made by Hauff-Technik have been available to energy supply companies for the construction of transformer stations for almost 40 years. However, hardly any attention has been paid to watertightness of walls or foundations and reliable sealing of cables in the foundations and towers of wind turbines. Expensive renovation and/or plant breakdown may in many cases be a possible consequence.

Subsequent sealing of foundations

The current standard and on-site 'lived' design for entries in foundations of wind turbines imitates the construction of basements and base slabs of single family homes or apartment blocks. If the local energy supplier does not stipulate any professional system, the contractor uses the most common wastewater pipes out of a sewage system in order to create wall penetrations. These pipes are inserted into the shuttering before pouring the on-site mixed concrete.

Wastewater pipes with water barrier placed in the reinforcement of the foundations

The inadequate adhesion of the on-site mixed concrete on plastic pipes has been known for a long time. For this reason, a suitable water barrier ('wall collar') is sometimes applied to the pipes which, however, requires time consuming installation on-site. Moisture or even water accumulates in the sewer pipes connected by simple plug-in sockets and without the above-mentioned water barrier the water will penetrate the building between pipe and wall. Construction workers then like to use Poly-urethane-based sealants in order to conceal any deficiencies in the sealing of these crucial points. In many cases, these polymer materials will at the same time be used to seal all power cables within the sewer pipe.

Unprofessional sealing of power cables on the outside of the foundations

These materials, which were originally intended to fix window-frames or door-frames in place, are obviously unable to cope with this task and only offer a short-term 'cheap solution' which will be all the more expensive at a later point in time.

In this environment, an appropriate renovation can be carried out using mechanical press seal system HRD. They can be used for individual application with a required pressure tightness up to 5 bar and with a 24-hour-availability if necessary. This means that any customer in Germany can hold his individual seal for any number of cables and cable diameters in his hands within 24 hours. The individual seals are specifically adapted to the sealing requirements of the customer and installed a thousand times each year – in quantities of one or multiples of this.

The press seal system HRD offers all possibilities for the reliable sealing of entries for one or several cables, as a closed seal insert during the initial installation or in split design for retrofit sealing. It does not matter whether one or more cables need to be sealed, if it is a centric or eccentric design or if the diameter is 50 or 1000 mm – safety and individuality are the first priority.

Renovation using standardized press seals with segment rings

In the instant case, seals with segment rings SG made by Hauff-Technik have proven to be particularly suitable for subsequent sealing of power cables in wind turbines. This seal version makes it possible for the user to adapt the seal to the number of cables and the cable diameters of the cables that have already been laid and to the respective pipe diameters - on-site worldwide. We can thus cover most applications with our standard types that can still be adapted to regional particularities.

A CNC-controlled production process cuts the so-called segment rings into the seal. The segment rings have a circumferential thickness of about two millimetres and can be removed during installation of the seal taking into account the cable and pipe diameters required. The result is a tolerance range of four millimetres for the medium pipe to be installed. The removal of individual segment rings thus allows the user to seal a cable or pipe within the respective tolerance range. This effortless adjustment of the seal to the required diameter allows the user easy and flexible installation on-site.

The perfect functioning of the segment ring technology has been proven by a test carried out at the VDE testing institute in Offenbach, where the seal withstood an IP 68K test as well as a 2.5 bar pressure test without any problems. It is yet another Hauff-Technik sealing system showing highest quality features: The press plates or press segments and bolts are made of V2A stainless steel and the rubber seals are made of EPDM or, upon request, of NBR. NBR is hightly resistant against oil, grease and all commercially available fuels.

New grids need new technologies

All requirements for absolute leak tightness, which have already been fulfilled in transformer stations and substations, must in future be taken into consideration in the planning stage by choosing an appropriate design of the foundation structures and the cable entry points. To ensure that no water can leak into the cable cellar of a tower foundation, it is necessary to use a concrete structure or concrete quality that is either waterproof by itself or can be made waterproof with appropriate outer coatings in which case it is of utmost importance to make the joints waterproof.

A DIBT guideline for wind turbines regarding impacts and structural stability proof tests for tower and foundations is available (version October 2012). It will be documented in a DIN standard and will be supplemented with important additions regarding drainage and wall sealings as well as stress classes. It seems reasonable to transfer the above-mentioned standards applicable to the construction of secondary substations and switchgear stations to the construction of foundations of wind turbines.

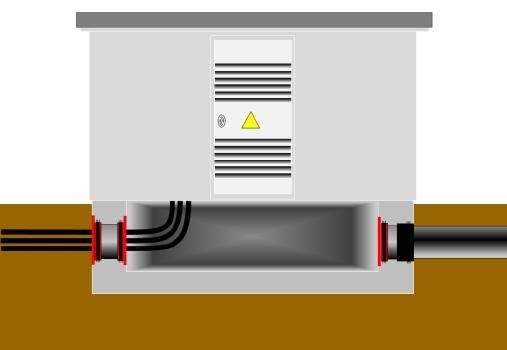

Professional sealing of power cables in a secondary substation

The HSI entry system is supplied with special plastic components which will allow for longitudinally watertight setting in concrete walls and professional sealing of cables on both sides. The wall inserts which are manufactured by two-component injection moulding from acrylic butadiene styrene and thermoplastic elastomer are equipped with industrially injected 3-ribbed seals in order to ensure absolute water tightness. These parts ensure a tightness up to the indicated waterpressure load of 2.5 bar where concrete and the medium to be set in concrete meet.

The closed system cover with bayonet catch prevents the penetration of water, mud or concrete during concreting and remains in place in order to ensure watertightness until the entry is used. For this purpose, the cover is equipped with a multi-ribbed radial seal along its external circumference which is already formed during production process. When the entry is used the closed system cover can be removed easily and without any tools and the required system cover can be installed. In order to verify its proper functioning, there is a quality seal label across the closed system cover and the wall insert. It is thus possible to visually check whether the closed system cover is still in its original condition or has already been removed once.

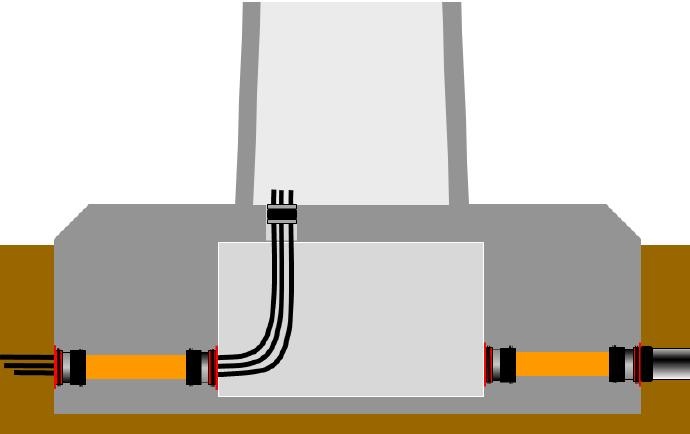

Suggestion for correct sealing of power cables in the foundations of wind turbines

Wall inserts are part of a modular system and once they have been set in concrete, they allow for an unusually broad range of applications for sealing of cables and for professional connection of rigid and/or flexible cable ducts. For the application in on-site concrete foundations, there is a special version available with integrated rubber plug-in socket GSM which can easily be pushed over both ends of rigid pipe conduits of diameters between 110 and 160 mm. It is thus possible to pre-assemble individual lengths with industrially prefabricated components for quick and reliable installation on the construction site.

The unique segmented ring technology also has a counterpart in the HSI system. The space-saving, permanently elastic DG system cover offers a pressure-tight, fast, simple and easy-to-handle sealing solution.

Authors:

Thomas Esswein, Applications Engineering, thomas.esswein@hauff-technik.de

Ralf Kurz, Head of Technology, ralf.kurz@hauff-technik.de

Uwe Lorenz, Sales Key Account Wind Energy, uwe.lorenz@hauff-technik.de

Dr Michael Seibold, Management, mailto:office@hauff-technik.de

- Source:

- Hauff-Technik

- Email:

- office@hauff-technik.de

- Link:

- www.hauff-technik.de/...